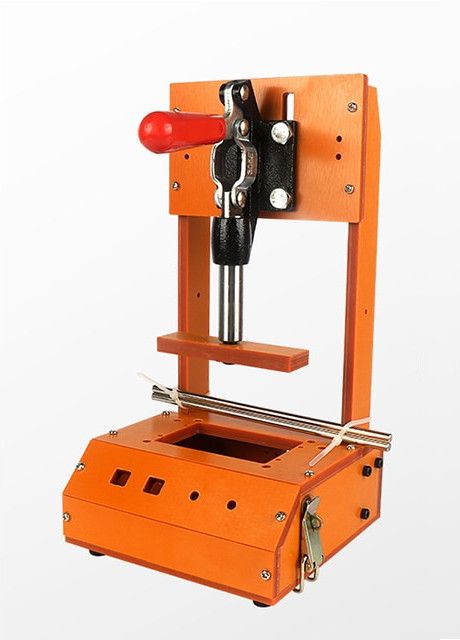

Hardware and firmware quality assurance begins, with attention placed on test driven development. We obtained a empty test harness to customise, as well as expanding our local fabrication laboratory with metal workshop machines to create manual test jigs. Schematic capture and layout design efforts are developing around the concept of distributing a general use transceiver device and several daughterboards.

| % | Milestone name |

|---|---|

| ✓ | |

| ✓ | |

| ✓ | |

| ✓ |

Components to be tested include Keystone standoffs for mounting to the jig and Mill-Max pogopins for connection to the test controller. A test plan includes unit tests documented in the firmware.